Taizhou Taisheng Metal Products Co., Ltd.

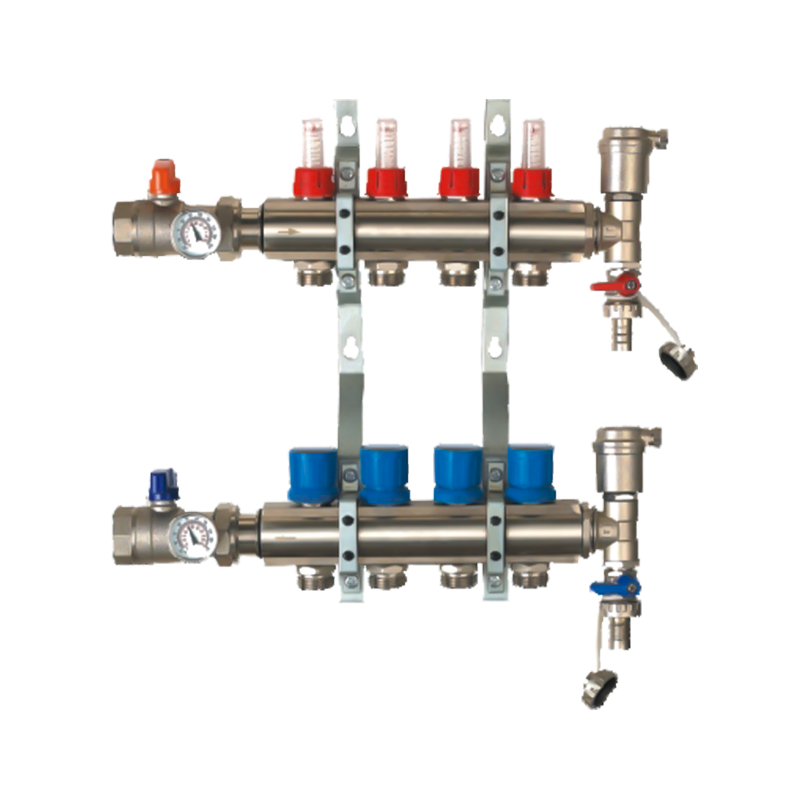

We are a professional China Brass Heating Manifold factory and custom Brass Heating Manifold company.The leading product is brass ball valve, brass angle valve, brass globe valve, brass check valve, water divider, brass pipe fittings, stainless steel fittings, hardware fittings.

The company has sophisticated production equipment and advanced testing equipment. We have CE, RoHS and ISO9001 certifications. The company's products are exported to the United States, Germany and other European countries for well-known brand enterprise manufacturers or provide OEM processing. With exquisite craftsmanship and innovative technology, it has been recognized in many aspects.

English

English 中文简体

中文简体 Español

Español Deutsch

Deutsch عربى

عربى

Home

Home